Driving is all about understanding the car’s physics and using that knowledge to manipulate the vehicle to do whatever you need it to do. Braking is a significant factor that contributes to establishing complete control over a car. It is the only way to slow down safely, but the way you brake impacts a vehicle’s weight distribution, which directly affects handling. Braking takes finesse, and that is precisely what progressive brake pads bring to the table.

The Basics of Automotive Braking Systems

Modern cars have all but done away with drum brakes. Most vehicles on the roads today run brake rotors in the front and rear. There are three main components to a modern brake system – the rotor, the brake pad, and the braking caliper.

The idea behind a braking system is fairly simple. You have a brake disc that spins freely and a brake caliper that is mounted over the disc. Each brake caliper contains two brake pads. Pressing the brake pedal pushes the brake fluid into the caliper, which in turn forces the brake pads to make contact with the disc. The friction caused by that contact is what slows down the car.

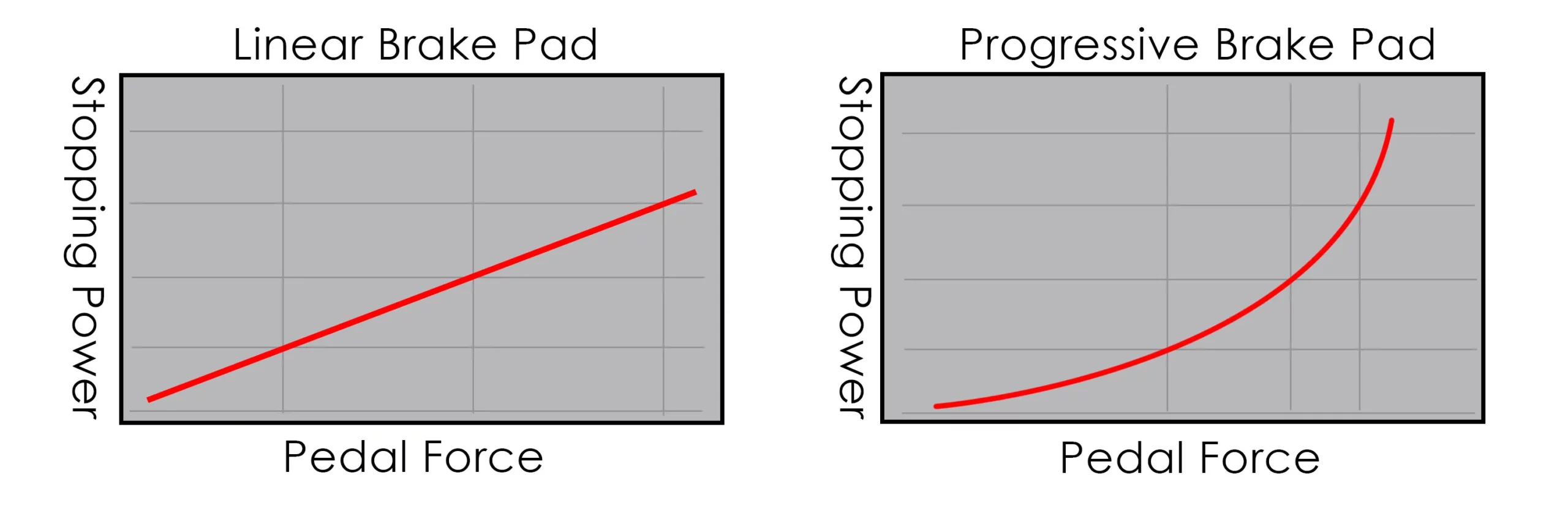

That being said, the way brake pads bite into the rotor matters. Standard OEM pads are pretty simple in the way they work – you press the brake, and the pads bite into the rotor, offering a linear amount of braking power.

While that works great for everyday commuting, a linear brake response isn’t all that ideal on the track. For that, you’ll need an upgrade.

Finding the Threshold

Braking is all about knowing exactly how far you can push your brakes and your tires. As you probably know, braking isn’t a binary function but rather a gradient. The more you push the brake pedal, the more braking power you’ll get.

With standard pads, this braking power gradient or curve is linear, and that’s perfectly fine for street use. Once you’re on a track or about to drive a rally stage, linear pads won’t cut it anymore. Why? They are too crude.

Performance driving, such as racing or rallying, requires a lot more finesse. If you’ve ever had a chance to watch the foot cam of drivers as they go around the track, you’ve probably noticed a lot of left foot braking and generally braking that doesn’t make much sense on the streets. These drivers are continuously riding the threshold where both the brakes and the tires are pushed to their limits. You can’t do that with linear pads.

Progressive Brake Pads

Riding the threshold requires a much more sophisticated tool – progressive brake pads, like EBC’s Yellowstuff and Bluestuff. The way progressive brake pads are designed allows you to modulate the amount of bite. A light press of the pedal will result in very little friction being applied to the rotors. However, as you increase the pressure, the braking power increases progressively.

Progressive pads allow for much more control and fidelity when braking. Additionally, this type of brake pads features advanced compounds capable of handling periods of sustained heavy braking. We’ll touch upon braking compounds a bit later. First, let’s define the difference between progressive and linear pads through a simple example.

Progressive VS. Linear Pads – What is the Difference?

By now, you’re probably wondering what the difference between progressive and linear pads is? After all, both of these types of pads brake harder, the more pressure you apply to the pedal, right?

Here’s a simple example. Let’s say that you’re navigating two left-hand corners that are spaced close to one another. Let’s see how navigating these corners would look like if you used linear pads.

As you’re setting up for the first corner, you’ve just reached the most optimal braking point. You’ve applied the brakes until the car slows down and you take the corner. While exiting, you have to completely release the brakes to stabilize suspension since linear pads bite hard even with a light press.

However, the next left-hander is right there, forcing you to get off the throttle and hit the brakes one more time. While doing so, you lock up the brakes ever so briefly, but you’re quick to let go of the brakes to compensate.

In the end, you’ve navigated both left-hand corners, but you’ve lost a lot of time because you couldn’t find the threshold when braking.

Let’s see how this same scenario plays out with progressive brakes.

You’re setting up for the first corner with the car riding the apex. As you reach the optimal braking point, you apply the brakes enough to slow the vehicle down as it travels through the corner. Upon exiting, you don’t need to release the brakes completely. Instead, you can reduce the amount of braking power by merely reducing the amount of force you’re applying to the pedal.

The car feels stable through the corner, and you apply more force to prepare for the next one. Let’s say that you overreact and lock the wheels. Instead of letting the brake pedal go completely, all you need to do is back off just a little, which is enough for you to find that threshold once again.

This ability to find the right amount of braking power depending on what you’re doing with the car is what makes progressive pads so good. It’s all about maintaining control.

Progressive Pad Compounds and Temperature Handling

What gives progressive pads the ability to modulate braking power is the compound they’re made of. The main difference between a progressive pad compound and a linear pad one is how they handle the heat.

Heat is a byproduct of friction. The way pads handle temperature has a massive impact on their performance. When a pad overheats, it loses a large chunk of its braking power. This is what’s called “brake fade.” Overheating is caused by sustained braking when the pad has no chance to cool off.

Linear pads can’t take long periods of sustained braking as they overheat reasonably quickly. That being said, your chances of forcing a linear pad into brake fade during a normal commute are slim to none. But, take linear pads to the track, and you’ll quickly find their limits.

On the other hand, progressive pads are designed to handle higher temperatures for long periods. Without this ability, there would be no point in having a progressive pad as it would overheat too quickly.

Which Pads Should You Get?

Choosing the right pads for your car will depend on your driving style, intended use, and more. If you’re into track days and amateur racing, progressive pads will prove to be a good investment. However, if you’re using your car strictly to commute, there’s no reason to use progressive pads.

Progressive brake pads often wear out faster and require brief warming up period before they’re at 100% efficiency. Now pair that with higher than average noise, and you have a combo that is not ideal for street use.

A very cool article..

Interesting article but it never follows up with what materials are used in “progressive” pads – a term that is new to me. Until now, I only knew of semi-metallic style pads and ceramic. However, the article puts some ceramic pads in this “linear” category, so, aside from a pad mfg describing its product as progressive (if they even do), how can one make an informed choice if the desire is to get progressive-style pads?!

Hey Tony, unfortunately I am no chemist and each brake manufacturer has their own formulations to make a pad behave a certain way. The specific formulations are all proprietary, so there’s a range of sliding scales effecting performance in the categories of heat range, overall friction, and hardness. In general, harder pads will be more progressive, and many ceramics (although not all) fall into that category. Several OE’s make pads that ship on new cars that are ceramic to help in longevity and dust, but are formulated be softer to feel more like a semi-metallic. Semi Metallic pads are generally much softer due to the heavy use of ferrous metal fibers as a bonding substrate, so they will be dustier and generally more linear due to higher initial friction or ‘bite’. Hope that helps answer your question.