One of the less appreciated facts about driving is that every time you go anywhere, you’re doing so by harnessing thousands of explosions. We’ve grown so accustomed to cars that we completely forget what’s going on under the hood. That blissful ignorance is something we can thank engine mounts for.

Needless to say, driving would be a very different experience without these simple but essential components. We’ll use this opportunity to explore the world of motor mounts, find out what they do, how they work, and much more. Let’s get to it!

What Exactly Are Engine Mounts?

Modern engines are smooth, silent, and almost unnoticeable when they work. However, a massive part of that perceived comfort can be attributed to engine mounts rather than the engine itself.

Your average motor is a place of extreme violence. If you think about it, every second that engine runs, fuel is being injected into its cylinders, compressed, ignited, and the exhaust pushed out the back. Rinse and repeat thousands of times every minute. Aside from pushing us forward, this process also produces a bunch of violent vibrations.

If you were to bolt the motor straight onto a chassis or the body of a car, it would be uncomfortable. One way to deal with this issue is to place dampers between the engine and the chassis, thus neutralizing all of those violent vibrations. These dampers are called engine mounts or motor mounts.

One of the less appreciated facts about driving is that every time you go anywhere, you’re doing so by harnessing thousands of explosions. We’ve grown so accustomed to cars that we completely forget what’s going on under the hood. That blissful ignorance is something we can thank engine mounts for.

Needless to say, driving would be a very different experience without these simple but essential components. We’ll use this opportunity to explore the world of motor mounts, find out what they do, how they work, and much more. Let’s get to it!

What Exactly Are Engine Mounts?

Modern engines are smooth, silent, and almost unnoticeable when they work. However, a massive part of that perceived comfort can be attributed to engine mounts rather than the engine itself.

Your average motor is a place of extreme violence. If you think about it, every second that engine runs, fuel is being injected into its cylinders, compressed, ignited, and the exhaust pushed out the back. Rinse and repeat thousands of times every minute. Aside from pushing us forward, this process also produces a bunch of violent vibrations.

If you were to bolt the motor straight onto a chassis or the body of a car, it would be uncomfortable. One way to deal with this issue is to place dampers between the engine and the chassis, thus neutralizing all of those violent vibrations. These dampers are called engine mounts or motor mounts.

https://www.youtube.com/watch?v=GL08scaXjOs

Damping Noise and Vibrations

Damping noise and vibrations coming from the motor isn’t merely a matter of passenger comfort. Sure, it would be highly uncomfortable to ride in a car that has the motor bolted directly onto the frame, but would it even be safe? Not really, no.

The vibrations caused by the motor when it idles just a small part of residual energy that needs to dissipate somewhere. You also have torque, road imperfections, and a whole slew of other things that need to be accounted for. Failing to neutralize all of these would most likely lead to the engine shaking itself apart.

The solution to the problem is rather simple. If you were to take any car and break it down to its individual parts, you would notice that the entire drivetrain is isolated from the rest of the car. The engine and the whole transmission system are suspended from the body using engine or transmission mounts, which are the same thing essentially.

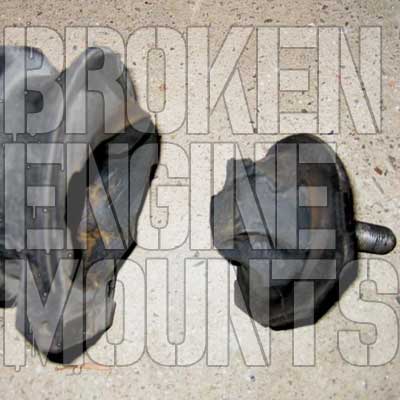

What Does an Engine Mount Look Like?

Your average engine mount is nothing more than a large piece of rubber sitting between two mounting points. Some motor mounts are square; others look like discs while some feature pretty unusual shapes. Some even come in the form of bushings, which depending on the make and model of your car. However, they all do the same job.

This sandwich of metal components and rubber has been subject to a fair bit of engineering. As it turns out, there are different types of vibrations out there. You can’t just slap a thick, rubber brick between the motor and the rest of the car and call it a day. There’s a bit more finesse to it. Engineers have recognized that the rubber’s stiffness plays a significant part in what kind of vibration motor support can neutralize. That’s why not all mounts are created equal.

The Anatomy of Motor Mounts

As you drive your car down the road, you’ll experience the vibration coming from the motor itself, but also the vibrations coming from the road surface. In other words, not only is it the job of an engine mounts to dampen the vibrations from the motor that dissipate outwards, but it also has to dampen the outside vibrations from going into the motor.

Different car manufacturers have resorted to different designs to achieve this damping flexibility. On the other hand, some have completely ditched the simple rubber mount in favor of much more complex systems. These include hydro mounts and electronic mounts.

Hydro Mounts

Using fluid to dampen vibrations is nothing new. This technology has been in use for a long time. The idea here is to simply use fluid to soak up as much of those vibrations as possible. Generally speaking, hydro mounts are effective, but they aren’t very durable. Some of them are known to last for years and years of service, but most aren’t that durable.

Hydro mounts tend to spring leaks over time, thus losing the precious fluid. Once that happens, you’re left with another hard mounting point that does nothing more but transfers vibrations into the passenger cabin. Oh, and hydro mounts are pretty expensive.

Electronic Engine Mounts

The use of electronic motor mounts is a fairly recent thing, at least if we’re talking about their wide-scale use. Electronic mounts or active mounts use various means to counter the vibrations. Most rely on a system of vacuum actuators controlled by a computer. The car is then able to dial in the mount’s stiffness based on the current vibration levels, engine RPM, and other parameters.

Needless to say, active engine mounts are very expensive to both produce and replace. However, they are often the most efficient system. Some will even produce a vibration of their own to cancel out the incoming or outgoing vibrations in the drivetrain system.

Why do Engine Mounts Fail?

Motor mount failure is not something that happens often, but it does happen. That being said, some motor mounts can last longer than the car itself. It’s a lottery, really.

Why motor mounts fail is a simple question with an even simpler answer – wear and tear.

Years upon years of constant vibrations will eventually wear out anything, including a piece of solid rubber. The constant movement makes the rubber lose its properties over time. Add to that the temperature cycles of hot and cold weather, and you have a perfect storm.

How Many Engine Mounts Are There?

The number of motor mounts in a car largely depends on the type of car it is. You’re looking at a different number of mounts for front-wheel drive and rear-wheel drive vehicles. On average, FWD cars will have three motor mounts, while RWD cars often come with only 2.

If you’re wondering why only two mounts for RWD cars, it’s because of the longitudinal layout. RWD cars often have one or two transmission mounts positioned in the back of the car, which complement the two engine mounts.

As for FWD cars, that extra motor mount is there to offer additional support since the whole drive train is built around the engine.

Knowing how many engine mounts your car has is a good piece of information to have. When engine mounts fail, they are often replaced as a group even though two out three might look just fine. The fact is that if one has failed, the rest are not too far behind.

How to Recognize a Failed Engine Mount?

Diagnosing bad engine mounts is generally much easier than you’d think. How can you tell that your mounts are gone? Easy, you’ll feel the whole engine moving. Aside from killing vibrations, engine mounts keep the engine fixed to the body of the car.

Incidentally, your engine wants to move. All of that torque that’s being transferred to the wheels requires the motor to be properly anchored down. Otherwise, some of the torque will make the engine move.

If you notice a clunk when you put a car fitted with an automatic transmission into gear, chances are your engine isn’t anchored down properly anymore. The same clunk can be experienced on sudden acceleration.

Additionally, you can always visually confirm engine mount failure. Have someone put the car in drive while you’re outside looking at the engine bay. Some movement of the engine is fine, but if it moves more than an inch or so, it’s probably time to swap the motor mounts.

Motor Mount Replacement

Replacing motor mounts is a fairly straightforward job. It usually comes down to removing the failed part and installing the new one. The process can be easy, but it can also be pretty tricky, depending on where the supports are located. On some cars, they are easy to access, but on some, they’re in a nightmare spot.

How to Find the Right Mount for your Car?

Here at eEuroparts.com, we offer a wide range of motor mounts for European vehicles. You can find the right type for your car by simply heading over to our online store and typing in your car make and model. Our system will then show you a list of parts that match your vehicle. Additionally, you can always type in your VIN. This will give you a much more accurate list of parts, especially if your car model came in different versions.

In case you have any questions regarding our selection of motor mounts, feel free to contact our customer support. We’re standing by to answer whatever questions you might have!

Dear Sir,

Appreciate if you could assist to explain for the below:

1. An Audi A5 was sustained badly accident impact on rear portion(the impact causes tailgate, bumper rear & rear panel require for replacement), is there any possible that the impact will cause the engine mounting RH & LH failure?

2. What is the life period for a new engine mounting?

Audi A5, year made 2009, odometer clock 54067KM.

A new engine mount should last around 80-100k miles, however an accident is capable of prematurely breaking these mountings. Generally, this usually happens only after the mounts have aged somewhat, and have been weakened over time. With such a low mile car I would be surprised if your Audi has broken engine mounts, but would not rule it out, especially if you have the electronic engine mounts described in the article, which are a little more delicate. Open the hood and with the car in park (or 1st gear), and your foot on the brake, give it throttle in both forward and reverse gear. If the engine moves around like in the video, you will need new engine mounts.

I have a 2005 ford Ranger 2.3. 86 k mechanic told me my mounts were all good but still having all of the symptoms ofor broken mount. sometimes when I shift to r and back to d i can feel one side of the truck lift and lower. vibration while on idle in the cab and you.can hear the dash vibrating . sometimes the transmission is kinda rough time when shifting could the mounts still be bad when a mechanic says they are fine. or can they be worn out but not broken or maybe the transmission mounts is bad what are you thoughts

If you are feeling these symptoms and the mechanic told you the vehicle is totally fine, I think it might be time to see a better mechanic. That sure does sound like a bad engine or frame mount somewhere. Sometimes mounts can be broken and look fine as they sit, but separate when put under load. Identify all the mounts that you can find, and have someone apply a slight amount of throttle in drive or reverse while standing on the brake. You should be able to see if something looks askew. A crowbar can also be used to lever mounts to view separation.

I have alot of engine movement on my Hyundai Amica when the revs are low it feels like it’s miss fireing could this be because my engine mounts are worn could it affect my engines performance when revs are high it’s fine it’s only when I slightly put the revs on it seems to miss fire abit and I thought it was because the engine mounts where worn can you help please

Hi I have a vauxhall vivaro van. I had a car hit the side of my front bumper at around 25mph straight after the engine started vibrating badly, could this have damaged the engine mounts

Absolutely, weak engine mounts can easily become broken engine mounts in accidents.

When I drive between 45 and 55 MPH my car vibrates, above and below those speeds it drives fine. I took it in and they balanced and rotated my tires and that didn’t fix it. I took it in for a transmission flush and fill and they noticed an engine mount was broken (which I never even told them I had symptoms of anything). I guess we will see if that fixed my problem!!

I hope that is the case, let us know for sure so we can all learn from your experience. Thanks Mark!

Hey, Mark~

Did the engine mount replacement fix the issue?

I have a 2005 Nissan Maxima and when I shift the car in reverse and drive it jerks and I when I excelerate it’s kinda sluggish. A guy “mechanic” says it’s the motor mount, I was thinking it was the transmission. I have to get other opinions.

Is it an automatic transmission? When was the last time you changed the fluid? Sounds like a combination of old fluid and worn mounts, but hard to judge without seeing it in person.

Hi I had my engine mounts replaced. Only to find this terrible noise after the work was done. Then the mechanic said ball joints. Got them replaced only to have to noise worse. So I did my brake pads. While jacked up from the cross member we noticed the four cross member bolts loose. So we tighten back up noise gone. But the mechanic won’t have it they forgot to tighten the cross member bolts back up. As there was no noise at all when went for new engine mounts. Then he tried telling me lower control arm bushes gone. Well the fact is I have photos of the cross member bolts hanging out. So after charging me for ball joints which where fine. Iam so mad as the mechanic is just blowing me of. I would have replaced lower control arm bushes only to have the same noise as you can only tell when the cross member is jacked up. I feel

The mechanic should refund the money for ball joints which I have paper work that they where done 8th month 2017 it was only 2019 January I took to the mechanic about the engine mount. It was only the left one broken. Bloody mechanic. And this ute was a council vehicle I have all the paper work from all. The service history plus it had only done 12000 thousand kilometres since ball joints where done. As they use hoist and would not of had a clue but kept charging me money for control arm bushes. Which are fine there was no noise before the engine mounts where done then I picked up with this terrible noise the young mechanic said ball joints so I did only to leave after paying all that money to fund noise worse. I rang him the boss I will go and talk to him the boss said. Iam not happy as ball joints last longer then 12000 thousand kilometres.

Hi, I have purchased two BWM vacuum hydraulic mounts. I have tested them prior to fitting and they both don’t hold any vacuum. Do you know if this is normal, or if they should be holding vacuum. Any help would be appreciated

Hi, I assume this is for a non-US market car? The answer is yes, the mounts should hold vacuum. Did you buy them used?

Hi Adam, yes this is for a non-us market car. They were both purchased brand new from BMW, I didn’t want to fit them knowing they didn’t hold vacuum. I think I should get them returned. Thanks for the advice.

Good luck, based on what I know they should hold vacuum, but two brand new mounts from BMW…the likelyhood of them both being bad is very slim to nil. Keep me updated if you end up with a set that does. Thanks.

Hi Adam, Mechanic replaced my car’s busted transmission (auto) with an after mart unit. Now there is more engine noise inside the car and I can feel more vibration than before. Could this be engine mounting problem or the transmission not installed properly? Noise and vibration more pronounce when gear is engaged. Less on neutral. Thank you for your advice.

It is quite possible that the engine mount was stressed or broken during installation or removal, when doing a job like this it is always a good idea to replace these mounts with new. You’re already spending the money, you might as well spend the few extra dollars for new mounts. After all of this, I think that it might just be the nature of the new transmission. You said aftermarket but I assume you mean rebuilt. That means that many parts were used from the original core. The best option would be to just kindly ask the mechanic about the new vibration and noises, they did the work after all.

Hello

I have a 2008 bmw 535xi

I know I have a bad right motor mount

Can the bad motor mount cause an issue when making a left turn slowly

I feel a vibration only on sharp left and the axel seems to be in fine shape

If the axle is for sure in good shape, then yes it sounds like an engine mount, or quite possibly sub-frame or differential mounts. You can use a crowbar and put pressure on your bushings and mounts to see if there is excess play. Also check your wheel bearings while the car is in the air.