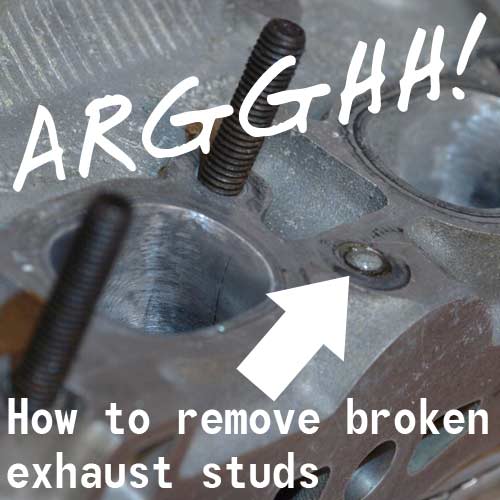

Wrenching on a car means that things will break from time to time. That’s just how it is. Whether you’re talking about head bolts breaking inside the engine block or exhaust studs breaking, it’s all part of the fun. It’s how you deal with these issues that will determine how much work you’ll have to put in.

Today, our goal is to give you a simple exhaust stud removal guide that will cut the work in half. Furthermore, you can apply some of these techniques elsewhere as they are pretty universal.

What is an Exhaust Stud?

Internal combustion engines burn fuel to create propulsion. The byproduct of combustion are exhaust gases. Hence, every engine has an exhaust manifold that leads the gases from the exhaust valves out back through the exhaust system.

Since the exhaust manifold isn’t built into the engine’s head, it has to be bolted on. The way this is often done is using studs or bolts. The problems start when these studs or bolts rust out or break either inside the head or flush with the head.

Why do Exhaust Studs Break?

There’s a couple of reasons why studs tend to break. One has to do with heat. Just like most things out there, metals expand and contract with heat. Each time you start the engine, and it warms up to its operating temperature, the studs will slightly expand. Each time the engine cools down, they contract. Of course, this is further accelerated by the weather where the rate of these temperature cycles is at its peak in the dead of winter.

Aside from heat, there’s always rust. Oxidation happens over time, especially if the car is frequently exposed to the weather. Having a rusted out exhaust stud is nothing out of the ordinary as it’s not so uncommon to find entire exhaust manifolds rusted to nothing.

How to Remove Broken Studs from the Head?

So you’ve decided to remove your exhaust manifold, and you’ve felt that notorious crack of a stud under your tool. Now what?

At this point, you have several options at your disposal. We’ll start with the easiest removal methods and work our way towards the more complicated solutions. More often than not, the easy way is all you need. In fact, you’d have to be super unlucky to find yourself in a place where you’d have to “Hail Mary,” a broken stud.

- Before we get to removing the broken stud, there are two crucial pieces of information you need to internalize.

Studs are generally not torqued too tight - A stud always breaks at an angle

Knowing these two facts is vital for what we’re about to do.

Two-Nuts Method

- Two Nuts

- A Pair of Wrenches

If you’re dealing with a stud that’s broken above the head, meaning that you have a small piece of it to work with, you’re in luck! The chances are that you can get it out using two nuts. Here’s how!

Thread the bolts as far don as you can on the stud. Now take one of the wrenches and hold the top nut as you start twisting the bottom one. The top nut will serve as a stop for the bottom one, essentially allowing you to undo the stud like you would a bolt.

Reverse this process when installing new exhaust manifold studs!

Drilling the Broken Bolt Out of the Head

Tools needed:

- A punch

- A Hammer

- Small drill bit

- An Easy-Out tool or a Hex bit

The first step in this particular method is taking a metal punch and tapping the broken stud. You’ll need to find a hammer that will allow you to do this as not all engine bays are permissive in this regard.

What you’re doing is creating a small divot in the broken stud. That divot is necessary to seat the pilot hole drill bit we’ll use to drill out the stud. Without punching a divot, the chances are that your drill bit would run all over the place or create a hole that is not perpendicular to the head.

After we’ve tapped the divot, take a small drill bit smaller than the stud’s diameter, and drill a pilot hole in the stud. Sometimes you’ll find that reversing the drill bit out of the stud is all it takes to remove it.

If not, we have two options on the table – we can either use the Easy-Out tool or use a Torx bit.

Easy-Out Method

An Easy-Out bit is a tool specially designed for extracting broken bolts. These are reverse threaded and come in various sizes. Find one that matches the size of the bolt.

Next, take the easy out tool and tap it into the pilot hole. Keep in mind that you might have to widen the pilot hole using a drill bit that is slightly smaller than the Easy-Out tool. With the tool biting the stud, take a small spanner and turn the Easy-Out bit in the counter-clockwise direction.

The Torx Bit Trick

Alternatively, if you don’t have an Easy-Out bit and your stud broke flush with the head, you can probably get away with a quality Torx spanner bit. Simply find one that will fit your pilot hole, tap it into place with a hammer and start turning it counter-clockwise. Remember how we said that exhaust manifold studs are rarely torqued tightly? That’s why you should be able to get away with a Torx bit.

The “It Can’t Be Tight if it’s Liquid” Method

Tools Needed:

- A Propane or Oxy-Acetylene torch

- A Wire Brush

- Locking Pliers

DISCLAIMER: Please don’t use propane or oxy-acetylene torch unless you have the necessary experience and knowledge. There’s a moderate risk of injury and property damage if you mishandle these tools. It’s much better to let a professional help you and handle this part of the job if you lack the necessary skills! eEuroparts.com is in no way liable for any injuries or damage to property resulting from attempting this repair.

Applying heat is always an excellent way to force unwilling bolts out of place. The idea is to heat the stud and the area around the stud until it expands. Once it has expanded, you can start working it out with the locking pliers.

Start by brushing the area around the stud with a wire brush. This will remove all of the contaminants that would otherwise burn. Next, take your torch and start applying heat evenly around the stud. Don’t stay too long in the same spot.

If you have an aluminum head, you’ll need to be extra careful. Aluminum will not glow when overheated. Instead, it will start to bubble, so be careful.

One the stud has been heated up properly, take your plyers and start working it. It should come right out.

Summary

Fixing a broken exhaust manifold stud can be a pain in the rear; however, it’s fixable. Methods shown above are some of the most common solutions used in the industry. However, if you feel that you’re not up to the task of extracting a broken stud, it’s better to let the pros take care of this one!

Great info thanks for sharing